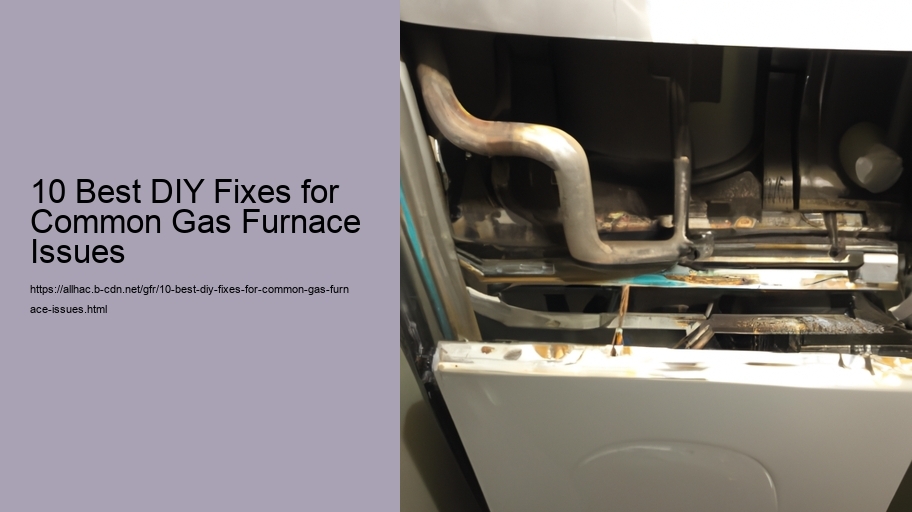

Troubleshooting a Non-Functional Thermostat

When it comes to maintaining a comfortable home environment during the chillier months, a properly functioning gas furnace is essential. Get in touch with All-Ways Heating & A/C for gas furnace repair services you can count on. However, like any household appliance, they can run into issues from time to time. One common problem homeowners may encounter is a non-functional thermostat, which can prevent your gas furnace from operating correctly or at all. Fortunately, with some basic troubleshooting steps, you can often resolve this issue yourself without needing to call in a professional immediately.

Firstly, verify that the thermostat is set to "heat" mode and that the temperature setting is higher than the current room temperature. This might seem obvious but it's an easy step to overlook. If your thermostat is programmable, make sure it has fresh batteries if it requires them and that its schedule is set correctly.

Next, examine whether there are any loose connections or wires within the thermostat housing. Before doing this though ensure that you turn off power to the furnace for safety reasons. Once safe to do so, remove the cover of your thermostat and gently inspect each wire ensuring they are securely attached to their respective terminals.

If everything appears in order internally with the wiring and settings, consider cleaning the inside of your thermostat. Dust and dirt can accumulate over time affecting its functionality. You can use a soft brush or compressed air to gently clean away debris that may be interfering with mechanical components or sensors.

Should these steps not yield results, another area to check would be your home's electrical panel for any tripped breakers or blown fuses related specifically to your heating system. Resetting a breaker or replacing a fuse may solve your problem if this was indeed the cause.

In addition, some thermostats require calibration from time-to-time in order to function accurately; consult your owner’s manual on how to calibrate your particular model correctly.

Lastly, if after going through these DIY fixes you find no resolution or are uncomfortable performing any of these tasks yourself—never hesitate calling in an HVAC professional. A certified technician will have no trouble diagnosing and rectifying more complex issues such as faulty internal components within either the thermostat itself or other parts of your gas furnace system.

Remember that regular maintenance is key in preventing many common problems associated with gas furnaces and thermostats alike. By keeping up on routine checks and cleanings you'll likely avoid having larger issues down-the-road while also extending the life-span of both appliances considerably.

Cleaning or Replacing the Air Filter

Cleaning or Replacing the Air Filter: A Key DIY Fix for Common Gas Furnace Issues

The heart of a cozy and warm home during the cold winter months is often a well-functioning gas furnace. However, like any other appliance, it can succumb to issues that may affect its efficiency and performance. One of the most common and easily remediable problems is a dirty or clogged air filter. Maintaining a clean air filter is not just about ensuring clean air circulation; it's crucial for the health of your furnace.

A clogged air filter can cause a multitude of problems for your gas furnace. It restricts airflow, which means your furnace has to work harder to circulate warm air throughout your home. This strain not only decreases efficiency, leading to higher energy bills but also increases wear and tear on the furnace's components, potentially shortening its lifespan.

Fortunately, cleaning or replacing an air filter is one of the simplest do-it-yourself fixes that homeowners can undertake without requiring professional assistance. Here’s how you can ensure this vital component remains in top condition:

Firstly, locate your furnace’s air filter. It is typically found in the blower compartment of the furnace, in an attached filter case or inside a return air vent.

Once you’ve found it, examine the condition of the filter - if it appears dusty or gray in color, it’s time for a cleaning or replacement. If you have a reusable filter, follow these steps: remove it from its housing and use a vacuum cleaner to remove loose dust particles before rinsing with water (ensure proper drying before reinserting). For disposable filters, simply measure the size and purchase an identical replacement from your local hardware store.

Replacing your filter regularly is key – every three months as general guidance or more frequently if you have pets, allergies or are located in high-dust areas.

By making sure that this simple task isn't overlooked, homeowners can greatly improve their gas furnace's performance while extending its life expectancy. Clean filters allow for better airflow and heat distribution while preventing dust from building up within the system - thus averting potential malfunctions.

In conclusion, never underestimate the importance of keeping your gas furnace's air filter clean. It's an easy yet effective way to prevent many common heating issues before they start. With minimal effort and expense involved in cleaning or replacing an air filter, there's no reason why this shouldn't be at the top of every homeowner’s maintenance list – ensuring that their abode remains comfortably heated through even the coldest winters.

Ignition System Fixes for Intermittent or No Heat

When dealing with a gas furnace that occasionally provides no heat or intermittent heat, the problem may lie within the ignition system. An ignition system is an essential component of a gas furnace as it is responsible for igniting the gas to produce heat. Here's how you can troubleshoot and potentially fix common issues related to the ignition system.

Firstly, identify what type of ignition system your furnace uses. There are generally two types: a hot surface ignitor or an older pilot light system. Newer furnaces often have electronic ignition systems which may either be intermittent pilot (IP) or hot surface ignition (HSI).

If your furnace has a traditional pilot light that won't stay lit, it could be due to a faulty thermocouple, dirty pilot orifice, or even drafts affecting the flame. To address this issue:

1. Ensure there are no drafts in the area by checking windows and doors for leaks.

2. Clean the pilot orifice with a needle to remove any debris that might be hampering the flow of gas.

3. Check if the thermocouple is positioned correctly in the pilot flame and tighten any loose connections.

4. If necessary, replace a defective thermocouple after turning off the gas supply.

boiler repair

For furnaces with electronic ignition systems:

1. If you have an intermittent pilot (IP) system that fails to ignite, inspect whether there is dirt obstructing the pilot opening or if electrical connections are secure.

2. With hot surface ignitors (HSI), look out for cracks on the ignitor element itself – this part is fragile and can fail over time; replacement will usually solve your heating issue.

Remember always to turn off electricity and gas supplies before attempting any fixes on your furnace's ignition system.

Keep in mind that consistent maintenance can prevent many issues from occurring in the first place. Regular cleaning of components and timely replacement of parts like filters help keep your furnace running smoothly.

However, not all fixes should be attempted as DIY projects – especially when dealing with complex systems like HVAC units where safety risks are involved due to high voltage electricity and combustible gases. If basic troubleshooting does not resolve your problem, it's best to call in a certified technician who has specialized training and equipment for diagnosing and fixing such issues safely and effectively.

In conclusion, while some fixes regarding an erratic or non-functioning heating situation can indeed be addressed through savvy DIY methods—particularly concerning older systems with simpler mechanisms—the modern complexity of most current furnaces means professional intervention may not only be preferable but necessary for proper function and safety assurance. Always prioritize caution over cost-saving when working on potentially hazardous home appliances like your gas furnace’s ignition system.

Resolving Blower Motor and Belt Problems

When it comes to maintaining a gas furnace, homeowners can often address some common issues without the need for professional help. Among these are problems related to the blower motor and its associated belt – components that are crucial for circulating warm air through your home. Here is a comprehensive guide to resolving blower motor and belt problems, which can be considered as one of the top 10 DIY fixes for common gas furnace issues.

Firstly, if your furnace blower motor isn't running at all, this could be due to a lack of power or a faulty motor. Begin by ensuring that the circuit breaker hasn’t tripped and that the switch on or near the furnace is in the 'on' position. If power isn't the issue, listen for any humming sounds from the motor; this could indicate that it's receiving electricity but is unable to turn due to seized bearings or other internal damage. In such cases, lubrication might help, but replacement is often necessary.

Secondly, if you notice that your furnace starts up but no air is coming out of your vents or the airflow is very weak, inspect the blower belt. Over time, belts can become loose or break due to wear and tear. Examine it for signs of fraying or cracks – if you find these symptoms present, replacing the belt should restore functionality.

To replace a worn-out belt:

1. Power off your furnace and open its access panel.

2. flame sensor cleaning Locate the blower assembly; typically found near where warm air exits.

3. Note how the old belt is routed before removing it – taking a picture might be helpful.

4. Loosen tension on pulleys (if applicable) so you can slip off the old belt.

5. Install a new belt according to manufacturer specifications and adjust tension correctly - too tight may strain bearings while too loose will slip.

6. Rotate by hand first to ensure smooth operation before powering back up.

Regular maintenance checks on belts should prevent sudden failures during cold months when furnaces work hardest.

Another aspect worth considering includes noises emitted from your unit which might suggest misalignment of pulleys causing undue wear on belts leading them fray faster than normal usage would dictate.

Finally do not forget safety precautions: Always turn off power supply before attempting any repairs ensure you have right tools potentially dangerous tasks like working with electricity mechanical parts should left professionals unless you feel confident abilities understanding risks involved

In conclusion tackling blower motor belt problems yourself save both time money However remember importance regular maintenance keep system running efficiently avoid emergencies proper care knowledge certain aspects heating system managed effectively providing warm comfortable environment through winter season

Flame Sensor Maintenance and Repair

Flame Sensor Maintenance and Repair: Essential Guidance for Tackling One of the 10 Best DIY Fixes for Common Gas Furnace Issues

When it comes to maintaining a comfortable home during the cold months, ensuring that your gas furnace is operating smoothly is crucial. A common issue that homeowners may encounter with their gas furnaces is related to the flame sensor. This small but vital component plays a critical role in your furnace's safety system by detecting whether a flame is present when the gas valve is open. If the sensor becomes dirty or faulty, it can prevent your furnace from igniting properly or cause it to shut down prematurely. Fortunately, with basic tools and a little know-how, cleaning or even replacing a flame sensor can be one of the top DIY fixes you can perform to keep your furnace running efficiently.

Before diving into maintenance and repair procedures, safety should always be your first priority. Ensure that you turn off the power and gas supply to your furnace to avoid any accidents. Once safe to proceed, you can locate the flame sensor by referring to your furnace’s manual—it's usually found near the burner assembly and looks like a thin metal rod sitting in front of one of the flames.

The process of cleaning the flame sensor is straightforward:

1. Remove: Carefully unscrew and remove the flame sensor from its mount.

2. Inspect: Look for signs of soot or corrosion on its surface.

3. Clean: Gently clean off any buildup using fine-grit sandpaper or steel wool—be careful not to apply too much pressure as this could damage the rod.

4. Wipe: After removing debris, wipe down with a clean cloth.

5. blower motor repair Reinstall: Place the cleaned sensor back into position and secure it firmly.

If after cleaning, you find that your furnace still struggles with ignition or sustaining a flame, then there might be an issue deeper than mere dirt accumulation—the sensor itself could be defective.

To replace a faulty flame sensor:

1. Identify: Confirm that replacement is necessary by testing with a multimeter or if visual inspection shows severe damage.

2. Purchase: Obtain an exact match for your model—using incorrect parts can lead to further complications.

3. Replace: Follow similar steps as cleaning but instead install a new sensor after removing the old one.

4. Test: After reassembly, restore power and gas supply then test if your furnace now operates correctly.

By addressing issues with your flame sensor promptly through regular maintenance—and knowing how to repair or replace it if needed—you save yourself time and money while avoiding more significant problems down the line.

Remember though these fixes are considered simple in nature; they do require some technical understanding and comfort working with appliances' electrical components—if ever in doubt about tackling such tasks yourself, seek assistance from qualified professionals who will ensure everything runs safely plus up-to-code standards.

Ensuring proper function of this tiny yet mighty piece not only contributes towards extending lifespan overall heating system also gives peace mind knowing family stays cozy warm without interruption all winter long!

Clearing Clogged Condensate Drains

As the winter chill sets in, a fully functional gas furnace becomes essential for maintaining a cozy home. However, like any other household appliance, furnaces are not immune to issues that can disrupt their operation. One common problem homeowners may encounter is a clogged condensate drain. This issue, if left unattended, can lead to water damage and reduced efficiency of your heating system. Fortunately, clearing a clogged condensate drain is often a manageable DIY task that doesn't require calling in the professionals.

Condensate drains are crucial for removing the water produced during the heating process. In high-efficiency gas furnaces, when natural gas burns to produce heat, it also creates moisture as a byproduct. This condensation typically exits through a pipe or drain line that leads away from the furnace into a floor drain or sump basin. Over time, this line can become blocked with debris such as dust particles or mold growth.

The first step in tackling this issue is locating the condensate drain tube attached to your furnace. Once found, inspect it visually for any obvious blockages or kinks which could be causing water backup. If you notice an obstruction within reach, gently remove it using appropriate tools—perhaps tweezers for small debris or softly pushing through with a wire if accessible.

If no blockage is visible but you suspect there's still an issue within the pipe itself, it's time to flush out the system. Begin by turning off power to your furnace for safety reasons before proceeding with any maintenance work. With power safely off, carefully disconnect the drain tube and use distilled vinegar to help dissolve any internal buildup; vinegar serves as an effective natural cleaning agent due to its acidity.

Pouring hot (not boiling) water mixed with vinegar down the drain can help break down mildew and other accumulations without damaging PVC pipes commonly used in these systems. Let this solution sit for half an hour before flushing out with more hot water; this should clear up minor clogs effectively.

In some cases where stubborn blockages persist after trying these steps, using compressed air or a specialized cleaning brush designed for piping might be necessary to dislodge whatever's causing trouble inside your condensate line.

Once you've successfully cleared out any obstructions from your condensate drain and reconnected everything securely back together again – don't forget to turn on your furnace! Regular monitoring of drainage flow after performing maintenance helps ensure no further problems arise and maintains optimal function of your heating system throughout those cold months ahead.

Clearing clogged condensate drains is just one example of how homeowners can tackle common gas furnace issues themselves without immediate professional intervention—saving both time and money while keeping their home warm and comfortable all season long.

Checking and Restoring Gas Supply Lines

Checking and Restoring Gas Supply Lines: A Key DIY Fix for Common Gas Furnace Issues

As winter approaches, the reliability of your gas furnace becomes crucial. Imagine a chilly night when you suddenly realize that your gas furnace is not working properly. Among the myriad of potential issues, disrupted gas supply lines can be a common culprit. Here's a brief guide to checking and restoring your gas supply lines – one of the top 10 DIY fixes for common gas furnace problems.

Firstly, safety should be your paramount concern when dealing with any gas appliance. Before you begin, ensure that all switches related to the furnace are turned off, including the electrical power switch and the gas valve. This precautionary step prevents any accidental ignition or electrical shock while you're working on the repairs.

Once you've ensured safety measures are in place, start by visually inspecting the gas supply lines for any signs of damage such as cracks or breaks. Physical damage to these lines can lead to leaks which are both dangerous and inefficient for your heating needs.

If there's no apparent physical damage but you suspect a leak due to a smell like rotten eggs (added odorant in natural gas), it’s time to perform a simple leak detection test. Mix some dish soap with water and apply this solution along the gas line connections. Watch closely for bubbles forming after spraying or brushing on this mixture; bubbling indicates escaping gas and thus, a leak.

Should you discover a leak at any connection point, tighten the joint using an adjustable wrench. Be careful not to overtighten which can cause further damage. After adjusting, reapply your soapy water solution to confirm that no more bubbles appear indicating that the leak has been fixed.

However, if there’s no evident sign of leakage or damage yet your furnace isn't receiving gas, check other components such as valves and regulators:

1) The main shut-off valve must be fully open.

2) The pilot light should be lit if applicable.

3) If equipped with one, make sure the thermocouple is functioning correctly.

4) Ensure pressure regulators are set correctly according to manufacturer specifications.

In some cases where troubleshooting doesn't resolve issues with supply lines or related components – especially when dealing with internal parts like valves – it might be best to call in professionals since they have specialized tools and expertise required for safe handling of potentially complex issues.

Restoring proper function to your gas furnace's supply lines is often straightforward but always prioritize caution over haste; never attempt repairs you’re unsure about especially when it comes to dealing with flammable substances like natural gas. With diligent attention and careful maintenance practices though many homeowners find that resolving basic issues within their heating system's fuel delivery mechanisms is within their capabilities - ensuring warm comfort through those cold spells without unnecessary intervention from professional services.

Resetting the Furnace’s Circuit Breaker or Replacing Fuses

Resetting the Furnace’s Circuit Breaker or Replacing Fuses: A DIY Guide for Common Gas Furnace Issues

As winter's grip tightens, a functioning gas furnace becomes more than just a comfort—it's a necessity. But when your warmth is interrupted by furnace failures, it can be both inconvenient and uncomfortable. Luckily, some common issues can be resolved with simple do-it-yourself fixes that don’t require an HVAC technician’s expertise. One such fix involves resetting the furnace's circuit breaker or replacing blown fuses.

When your gas furnace stops working, one of the first things to check is the electrical system that powers it. Often, the problem may be as straightforward as a tripped circuit breaker or a blown fuse. These components are designed to protect your home from electrical overloads and short circuits. If they trip or blow, they will cut off power to prevent potential damage to your furnace and house.

To reset the circuit breaker for your gas furnace:

1. Locate your home's electrical panel – usually found in basements, garages, utility rooms, or closets.

2. Open the panel door and look for a switch labeled "Furnace" or "HVAC." It might have tripped from its "On" position to a neutral position.

3. Flip the switch all the way off and then turn it back on firmly—this should reset it.

4. Check if your furnace starts operating again after this step.

If you find that there isn't any issue with the circuit breaker or if it continues to trip after being reset (which suggests further issues), you may need to check if any fuses have been blown.

To replace a blown fuse for your gas furnace:

1. Identify where the fuse block or holder is located; this could either be within your main electrical panel or inside another box near your furnace.

2. Turn off power at the main switch before proceeding with replacing any fuses.

3. Carefully remove the suspected blown fuse — it might appear discolored or blackened compared to others if indeed blown.

4. Replace it with an exact match in size and amperage rating; using incorrect fuses can cause significant harm both to you and your equipment.

5. Once replaced, turn on power at main switch again.

In either case of resetting breakers or replacing fuses, remember that safety comes first: never handle electrical components without ensuring everything is de-energized appropriately.

While these steps may resolve some problems immediately, frequent trips of breakers or blowing of fuses often indicate deeper issues within your system - ones that may require professional diagnosis and repair.

Remember too that preventive maintenance plays an important role in preventing such occurrences altogether; regular checks on filters, vents, wiring connections can save you time and money down the line while ensuring warm winters spent in comfort rather than cold anxiety awaiting repairs.

By knowing how to confidently tackle simple issues like resetting breakers and replacing fuses yourself, not only do you become more self-reliant but also gain knowledge about how integral systems in your home operate—a win-win scenario during those chilly months!