Conducting a thorough inspection before initiating repairs

Conducting a thorough inspection before initiating repairs on a gas furnace is an essential step that sets the tone for efficient and effective service. Get in contact with All-Ways Heating & A/C for gas furnace repair services you can count on. This proactive approach allows technicians to accurately diagnose issues, plan out their repair strategies, and ensure that all aspects of the furnace are functioning correctly after the fix. It's akin to a doctor performing a full check-up before prescribing treatment—a necessary due diligence process.

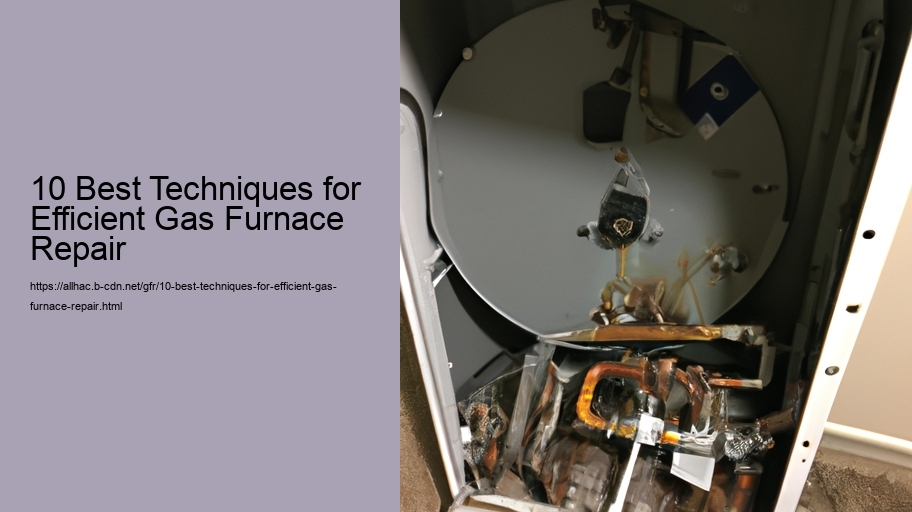

Before diving into any hands-on work, it's crucial for technicians to start with a visual assessment of the entire system. This involves examining external components for signs of wear, corrosion, or damage that could hint at underlying problems. Such scrutiny can reveal surface-level issues that might otherwise go unnoticed until they develop into more significant malfunctions.

Following this preliminary review, attention must be turned inward. Inspecting internal components like the heat exchanger, burner assembly, ignition systems, and blower motor is critical since these play pivotal roles in the operation of the gas furnace. A meticulous examination helps uncover any potential safety hazards such as cracks in the heat exchanger which could lead to dangerous carbon monoxide leaks.

The inspection phase should also include checking electrical connections for tightness and integrity because loose or corroded wires can lead to intermittent operation or even complete failure of the system. Similarly, confirming proper gas pressure and flow ensures that the furnace will burn fuel efficiently and safely.

Another key element is testing controls and thermostats to make sure they are communicating correctly with the furnace. Miscommunication between devices often leads to erratic heating behavior which not only affects comfort but also drives up energy bills due to inefficient operation.

Moreover, inspecting air filters and ductwork plays an important role in maintaining healthy air quality and airflow dynamics within a home. Clogged filters or obstructions in ducts force furnaces to work harder than necessary which can shorten equipment lifespan while compromising performance.

A comprehensive inspection must culminate in reviewing venting systems since an improperly vented gas furnace poses serious health risks from exhaust gases. Ensuring vents are clear from blockages and verifying they adhere to code requirements are paramount steps in guaranteeing safe operation.

In summing up, conducting a thorough inspection before initiating repairs serves multiple purposes: it identifies current issues accurately; prevents future problems by catching early warning signs; ensures safety by identifying hazardous conditions; maintains optimal energy efficiency; extends equipment longevity; and assures customers' peace of mind knowing their heating system has been meticulously examined by professionals who have left no stone unturned in safeguarding their comfort and well-being.

Cleaning or replacing the air filter regularly

Maintaining an efficient gas furnace is crucial not only for ensuring a warm and comfortable home during the colder months but also for keeping energy costs down and prolonging the lifespan of your heating system. Among the 10 best techniques for efficient gas furnace repair, cleaning or replacing the air filter regularly stands out as a simple yet highly effective measure.

The air filter in a gas furnace plays a critical role in protecting the internal mechanisms from dust, dirt, and other airborne particles. When these contaminants accumulate on the filter, they can obstruct airflow, forcing the furnace to work harder to circulate warm air throughout your home. This additional strain not just leads to decreased efficiency but can also cause wear and tear on the system components over time.

Regularly inspecting and changing your air filter is one of the easiest maintenance tasks you can perform on your furnace. A clean filter ensures that air moves freely through your heating system, which helps maintain optimal performance levels. The frequency at which you should clean or replace your filter can vary depending on several factors such as usage patterns, type of filter, presence of pets, and level of indoor pollution.

For most households, checking the air filter monthly during peak usage seasons is advisable.

10 Best Techniques for Efficient Gas Furnace Repair - ventilation system inspection

- carbon monoxide testing

By ensuring that this vital component of your gas furnace remains unclogged and functioning correctly, not only do you enhance its efficiency but also contribute towards maintaining good indoor air quality—a benefit for all occupants' health within your household.

In conclusion, while there are many aspects to consider when aiming for an efficiently running gas furnace—such as regular inspections by professionals, thermostat calibration, ductwork checks—cleaning or replacing the air filter stands out due to its combination of simplicity and impact on overall system performance. It's a small step in routine maintenance that yields significant returns in terms of both energy savings and equipment longevity.

Checking and maintaining the furnace's ignition system

Checking and maintaining the furnace's ignition system is a critical component of ensuring your gas furnace operates efficiently and safely. The ignition system serves as the starting point for your furnace, igniting the fuel to produce heat. Without a properly functioning ignition system, your gas furnace can fail to start or may operate unsafely, leading to potential hazards such as gas leaks or carbon monoxide poisoning.

Modern gas furnaces use one of several types of ignition systems: the conventional standing pilot light that remains lit at all times; intermittent pilot systems that ignite the pilot flame only when needed; or hot surface igniters or spark igniters that directly light the main burners without a pilot flame.

Maintaining these components requires a careful approach and an understanding of their operation. For instance, a standing pilot light needs regular checking to ensure it hasn't gone out and is burning with a steady blue flame. If it frequently goes out, there could be issues with thermocouples or drafts in the unit.

Intermittent pilots and electronic igniters are more complex but offer greater efficiency. They should be inspected regularly for signs of wear and replaced before they fail completely. Dust and debris can accumulate on these parts over time, hindering performance, so cleaning them carefully with appropriate tools is essential.

A key part of maintenance involves checking electrical connections associated with the ignition system to make sure they are firm and not corroded. flue pipe sealing Loose or corroded wires can lead to poor performance or even dangerous situations where electricity cannot reach its intended destination.

In addition to these checks, general inspection around the ignition area is advisable—looking for signs of damage such as cracks in ceramic components which might indicate stress from heat or improper installation.

Professional HVAC technicians have specialized equipment like multimeters to check voltage levels and other parameters that indicate if an ignition component is working within its specifications. For most homeowners though, visual inspections and basic tests (like ensuring a pilot light is lit) are enough for routine checks between professional service appointments.

It's also important not just to maintain but also understand safety features built into modern furnaces such as flame sensors which shut down fuel supply if they detect unburned gas accumulating due to failed ignition—a feature that underscores why proper care of this system isn't just about efficiency but crucially concerns safety too.

Given its importance for both operational reliability and household safety, keeping up with maintenance on your furnace's ignition system should be seen as both a responsibility and an investment—an action that ensures comfort during cold months while guarding against risks inherent in operating any combustion-based heating equipment.

10 Best Techniques for Efficient Gas Furnace Repair - carbon monoxide testing

- safety controls assessment

Ensuring proper airflow by inspecting and cleaning blower components

When it comes to maintaining and repairing gas furnaces, one of the critical aspects that often gets overlooked is the importance of ensuring proper airflow. A furnace relies on a steady circulation of air to operate efficiently and safely. Over time, blower components can accumulate dust, debris, and other obstructions that can hinder this essential airflow. Therefore, inspecting and cleaning these components is not just a recommended maintenance task—it's an imperative step in efficient gas furnace repair.

The blower assembly includes several parts: the blower wheel, motor, and fan housing. Together these components work to move air through the heat exchanger and then circulate it throughout your home. If any part of this system becomes dirty or clogged, it can lead to a range of problems from reduced efficiency to potential safety hazards.

The first benefit of regular inspection and cleaning is improved efficiency. When blower components are free from obstruction, they require less energy to move air effectively. This means that the furnace doesn't have to work as hard or run as long to achieve the desired temperature setting—ultimately reducing wear on its parts and saving on energy bills.

Safety is another crucial reason for keeping blower components clean. A dirty or obstructed blower wheel can cause poor airflow which may lead to overheating. In extreme cases, this could result in a heat exchanger cracking—a potentially dangerous situation as it could allow carbon monoxide to enter your living space.

Additionally, clean blowers contribute significantly towards better indoor air quality by preventing dust and allergens from being recirculated into your home's air supply. For individuals with allergies or respiratory concerns, this aspect alone underscores the value of maintaining clear blower passages.

To ensure thorough inspection and cleaning of blower components during gas furnace repair:

1) Power down the furnace completely for safety.

2) Access the blower assembly according to manufacturer instructions.

3) Visually inspect all elements for signs of buildup or damage.

4) Use a brush attachment on a vacuum cleaner to gently remove loose debris from around the motor and within the fan housing.

5) Clean individual blades of the blower wheel carefully; sometimes removing it for more effective cleaning is necessary.

6) Check belts (if applicable) for proper tension and wear.

7) Lubricate moving parts if specified by manufacturer guidelines.

8) Reassemble all parts securely before restarting the furnace.

By incorporating these steps into routine maintenance schedules—or addressing them specifically during repairs—technicians ensure that a gas furnace operates at peak performance levels while also extending its service life.

In conclusion, never underestimate how much something as seemingly small as cleaning can impact overall system functioning. Ensuring proper airflow through regular inspection and meticulous cleaning of blower components isn't just good practice; it's one of the best techniques for efficient gas furnace repair that yields tangible benefits such as energy savings, prolonged equipment lifespan, enhanced safety measures, and improved air quality within homes.

Examining and calibrating the thermostat for accurate temperature control

Examining and Calibrating the Thermostat for Accurate Temperature Control

In the realm of gas furnace repair, meticulous attention to every component is crucial for maintaining an efficient system. Among these components, the thermostat holds significant importance as it serves as the command center for temperature regulation within a home. Ensuring that this device is accurately calibrated can lead to substantial improvements in both comfort and energy efficiency.

The process of examining and calibrating the thermostat begins with a thorough inspection. Technicians must first ensure that the thermostat is correctly positioned away from any heat sources, such as sunlight or appliances, which could skew its readings. The location should also be central to average room temperatures for more accurate detection of ambient warmth.

Once a proper position is confirmed, technicians proceed with testing the thermostat's responsiveness. They may raise or lower the set temperature to observe whether the furnace responds appropriately by activating or deactivating. Should there be any delays or discrepancies in response time, it indicates potential issues either with wiring connections or internal mechanisms within the thermostat itself.

Calibration forms a critical part of this examination process. Over time, thermostats may drift from their original settings due to aging components or external influences. A misaligned calibration can cause your furnace to cycle too often or not enough, resulting in uncomfortable temperature swings and increased wear on furnace parts—both factors contributing to inefficiency and higher utility bills.

Using specialized tools like a multimeter and reference thermometers, technicians can determine if there’s a mismatch between what the thermostat displays and actual temperatures. Adjustments are then made internally within the device according to manufacturer specifications until accurate readings are consistently achieved.

For digital thermostats equipped with sophisticated programming options, technicians might perform software updates or reset procedures as part of calibration efforts. Analog units typically require manual adjustments—a delicate process necessitating expertise so as not to compromise sensitive mechanical components.

In certain cases where calibration proves unsuccessful due to hardware limitations or malfunctions beyond repair, replacing an old thermostat with a modern programmable model could be recommended. These newer devices offer precise control over heating patterns tailored to one’s lifestyle while promoting energy savings through customizable scheduling features.

Ultimately, examining and calibrating the thermostat is about striking harmony between user demands for comfort and the operational efficiency of their gas furnace systems—an intricate dance best performed by skilled professionals who understand both technology intricacies and human preferences alike.

Inspecting heat exchanger for cracks or signs of wear

Inspecting a heat exchanger for cracks or signs of wear is a crucial step in maintaining and repairing gas furnaces to ensure their efficiency and safety. A heat exchanger is an integral component of a gas furnace that transfers heat from the combustion gases to the air circulating within the ductwork of a home, without allowing the two to mix.

Over time, due to constant heating and cooling cycles, the metal of the heat exchanger can suffer from stress which may lead to cracks or other forms of wear. Even small fractures can have serious consequences, such as allowing harmful combustion byproducts like carbon monoxide to enter the living spaces. Therefore, regular inspection is one of the best techniques for efficient gas furnace repair.

To start with, visual inspection is often performed using strong lighting and mirrors to check for any visible signs of damage on the surface of the heat exchanger. This includes looking for rust, corrosion, soot buildup, or any deformities that might indicate a problem.

Technicians also employ more advanced methods such as using a camera scope specifically designed for inspecting internal surfaces. furnace filter upgrade These scopes can get into tight spaces and provide clear images of areas that are difficult or impossible to see with just the naked eye.

Another technique involves conducting a smoke test where safe smoke bombs are placed inside the heat exchanger while it's sealed; if there are cracks or holes, smoke will leak out indicating where repairs are needed. Additionally, some technicians use chemical detectors that can pick up traces of gases that would escape through tiny fissures not easily seen during a visual examination.

A pressure test is another method used wherein air is pumped into the heat exchanger at a specific pressure. If there's a reduction in pressure over time without an obvious escape route for air, this implies there may be small unseen holes present.

Once any defects are identified during inspection, immediate action should be taken either by sealing minor cracks with appropriate high-temperature sealants or by replacing severely damaged sections or even entire units depending on the severity and location of damages found.

Regularly inspecting your gas furnace’s heat exchanger not only ensures efficient operation but also protects against potential safety hazards. It's important that these inspections are performed by trained professionals who have the knowledge and tools necessary to detect problems early on and carry out repairs effectively – safeguarding both performance and peace of mind for homeowners.

Verifying and maintaining correct gas pressure and flame operation

Verifying and maintaining correct gas pressure and flame operation is one of the most crucial techniques for ensuring the efficiency and safety of a gas furnace repair. This process, when carried out with precision and care, can greatly improve the longevity of a furnace while also optimizing its performance.

The heart of a gas furnace's functionality lies in its ability to combust fuel safely and effectively, producing heat to warm up a space. When the gas pressure is either too low or too high, it can lead to problems such as incomplete combustion, soot buildup, or even dangerous conditions like gas leaks or explosions. Therefore, verifying that the pressure is set according to manufacturer specifications is paramount.

To begin this verification process, a technician must be equipped with the appropriate gauges and tools. A manometer is commonly used for measuring gas pressure. The technician will connect this device to the furnace's pressure tap and monitor the reading. If adjustments are necessary, they will manipulate the regulator or adjust settings on the furnace until achieving optimal levels.

Flame operation is equally important as it indicates how well fuel combustion occurs within the unit. A healthy furnace flame typically burns blue with perhaps just a hint of yellow at the tip - indicating efficient burning of natural gas which predominantly consists of methane. An unstable flame that flickers excessively or displays colors like yellow or orange throughout suggests an issue such as dirty burners, improper venting or air supply issues.

Maintenance comes into play once initial verification has been completed successfully; it ensures that proper conditions are sustained over time. Regularly scheduled check-ups should include cleaning burners and jets to prevent blockages that could affect both pressure and flame quality. Air filters should be replaced consistently to ensure there is adequate airflow for combustion.

Another aspect involves monitoring changes in performance between service visits which could indicate shifting pressures or other emerging issues with flame operation – homeowners might notice different sounds from their furnaces or changes in heating effectiveness which should prompt them to call for professional assistance.

For technicians aiming at delivering best-in-class services in efficient gas furnace repair, mastery over these practices becomes indispensable: knowing how each adjustment affects overall system performance helps not only in immediate repairs but also in advising clients on effective maintenance practices going forward.

Ultimately, by focusing on verifying and maintaining correct gas pressure and flame operation through skillful assessment and diligent attention to detail during repair jobs, technicians can significantly enhance not just the operational efficiency but also extend the lifespan of residential heating systems while ensuring user safety – making this technique an essential component among the top strategies for proficiently repairing gas furnaces.

Scheduling annual professional maintenance checks

Scheduling annual professional maintenance checks is one of the ten best techniques for efficient gas furnace repair and it plays a crucial role in ensuring the longevity and efficiency of your heating system. This preventive measure goes beyond the immediate fix; it's about averting problems before they escalate into costly repairs or even complete system failures.

The essence of these professional checks lies in their thoroughness. Skilled technicians inspect every component of your furnace, from burners to heat exchangers, blower motors to thermostats, and filters to safety controls. They look for signs of wear and tear, corrosion, and other potential issues that may not be evident to the untrained eye. It is this proactive approach that can save homeowners from the inconvenience of unexpected breakdowns during peak winter months when furnaces are under maximum strain.

During these inspections, technicians will often clean components that have accumulated dirt and debris — a common cause of reduced efficiency and part malfunction. A well-maintained gas furnace doesn't have to work as hard to produce and distribute heat, which means it uses less energy and keeps utility bills lower.

One must not underestimate the importance of safety either. Gas furnaces involve combustible elements; any leaks or faults could pose serious health risks such as carbon monoxide poisoning or fire hazards. Annual checks ensure all safety protocols are rigorously adhered to, keeping you and your loved ones safe.

Furthermore, regular maintenance can extend the lifespan of your furnace significantly. Just like any mechanical system, parts wear out over time; however, catching issues early can mean simple replacements rather than full-scale repairs or even premature replacement of the whole system.

Another advantage often overlooked is warranty preservation. Many manufacturers require proof of regular maintenance when claims are made under warranty. Skipping annual checks could void this protection leaving you exposed financially should major components fail within what would have been the covered period.

In conclusion, while there may be an upfront cost associated with scheduling annual maintenance checks for your gas furnace, it is an investment that pays dividends in terms of reliability, efficiency savings on energy bills, safety assurance, extended equipment life span, and maintained warranties – making it one among many essential strategies for efficient gas furnace repair management. Remembering to book these appointments ahead of each heating season ensures peace of mind throughout those cold months when warmth at home is most cherished.